Nursing

We chose to focus on the nursing domain because many James Dyson Award winners have tackled healthcare challenges reflecting the award’s emphasis on life-improving, practical design. Nurses are often first responders in critical situations, and their needs are central to ensuring effective patient care. Our solution aims to support them by addressing key gaps in workload management.

Firefighting

We chose to explore the firefighting domain after noticing that several James Dyson Award winners have focused on emergency response and life-saving innovation. Firefighting presents high-risk, time-critical challenges where every second counts. Our goal was to understand the operational demands and pain points faced by frontline responders, and to explore how our solution could support safer, faster, and more effective rescue efforts.

1.Domain Analysis

We began by building foundational knowledge understanding key terminology, context, and existing practices within the domain. This ensured that we shared a common language with stakeholders and could engage meaningfully without misunderstanding technical terms.

Firefighting is one of the core operational functions under SCDF which Involves:

-

Building fire suppression

-

Rescue operations

-

Fire prevention and enforcement

-

Deployment of firefighting tech and gear

Frontline firefighters are the first responders directly engaging in fire and rescue operations

They operate in:

-

High-heat, low-visibility conditions

-

Life-threatening, time-sensitive situations

-

Teams coordinated by incident command

Tools and Systems Used by Firefighters:

-

Personal protective equipment (PPE)

-

Self-contained breathing apparatus (SCBA) for protection

-

Thermal Imaging Cameras (TICs)

-

Radios for comms and info

-

Command support systems (e.g. dashboards, building layout data)

Why Focus on Frontline Firefighters?

-

Physically and mentally demanding role

-

Critical to public safety and survival

-

High dependency on effective systems and tools

-

Opportunity for tech innovation to support safety, awareness, and decision-making

2.Stakeholder Interview

We conducted open-ended, non-leading interviews with domain experts to learn about their standard operating procedures (SOPs) and the challenges they face. This step helped us uncover real-world pain points without introducing bias.

Muadz, Ns Firefighter,Punggol Fire Station Interview 1

1. Could you share what a typical day at the fire station was like for you during your NS?

-

Worked on a 24-hour duty followed by 48 hours of rest.

-

Started each shift at 8:00 a.m. with equipment checks and crew assignments to specific vehicles.

-

Daily routine included drills, downtime, cleaning duties, physical training, and night lectures.

-

Always had to be ready for emergency calls at any time.

2. What kind of roles and responsibilities did you personally handle on a regular basis?

-

Responded to emergencies, conducted rescues, and fought fires.

-

Ensured personal and team safety.

-

Participated in all routines like drills, cleaning, lectures, and fitness training to stay prepared.

3. How did your team typically prepare for an emergency call? Was there a specific routine or protocol you followed?

-

Strict one-minute turnout time after the alarm.

-

Practiced wearing gear and using equipment quickly.

-

Reconfirmed SOPs en route to the incident.

-

Familiarity with multiple incident categories (e.g., fire types, suicide rescues, cardiac arrests, chemical incidents).

4. When responding to different types of incidents, how were tasks usually divided among the team?

-

Fire: nozzleman, breaker, commander, support crew.

-

Suicide Rescue: net setup, floor intervention, negotiation.

-

Cardiac Arrest: CPR and airway management.

-

Road Accidents: victim rescue or body retrieval.

5. Were there any tools or equipment you relied on the most during operations? Were there any that felt outdated or inefficient?

-

Heavily relied on bolt cutters, power saws, thermal imagers, rabbit tools, breaching tools, hydraulic spreaders/cutters, and reciprocating saws.

-

Power saws, chainsaws, and generators were often hard to start and unreliable.

-

Battery-operated tools required constant attention.

6. What parts of your daily routine or emergency response felt repetitive or unnecessarily manual?

-

Daily equipment checks felt tedious but were necessary.

-

Repetitive tasks like fuel top-ups, manual tool warm-ups, and generator prep consumed time and felt outdated.

7. Were there moments during an operation where you felt like more coordination or support could’ve helped the outcome?

-

Situations involving faulty hydrants, risers, or lifts required heavy improvisation and caused delays.

-

Better advance intel or maintenance reporting could have helped avoid these inefficiencies.

8. What kind of non-fire-related emergencies did you respond to most often?

-

Most frequent were cardiac arrests and suicide rescues.

-

Required collaboration with medical and police services.

-

Demanded emotional intelligence and calm under pressure.

9. Could you walk me through how you and your team would approach a suicide rescue or similar high-risk situation?

-

Emphasis on stealth and coordination to avoid alarming the victim.

-

Multi-level deployment: rescuers above and below the victim.

-

DART support involved roof access and rope rescues.

-

Could escalate to CPR if victim jumped.

10. What are some of the biggest bottlenecks when trying to save a suicide victim?

-

Lack of clear initial intel on victim’s location or condition.

-

Locked or faulty access routes.

-

Setup time for high-angle rescue equipment added delay.

11. What factors usually slow things down or make those kinds of situations especially difficult to handle?

-

Victim’s fragile mental state slowed response.

-

Communication barriers and silence from the victim increased complexity.

-

Required calm, empathetic, and cautious team behavior under pressure.

12. Were there ever moments where communication or decision-making became a challenge on-site?

-

Occasional internal disagreements or miscommunications about tasks/tools.

-

Poor decisions or unclear leadership sometimes had serious consequences.

13. If there was one thing you wish you had that would’ve helped make your job easier or safer, what would it be?

-

Stronger team chemistry would enhance effectiveness.

-

Lighter, more ergonomic bunker gear.

-

Health/status tracking tech for real-time updates on team member safety during operations.

3.Need Formation & Validation

Using insights from interviews, we synthesized preliminary user needs. We then held follow-up interviews to validate and refine these needs, ensuring they were accurate, relevant, and meaningful to the stakeholder.

Identified Needs

Operational Needs

-

Quicker and more reliable equipment startup

-

Chainsaws and power tools often failed to start during operations.

-

-

Faster preparation and cleanup of gear

-

Gear prep and cleanup before and after duty take significant time and effort.

-

-

More efficient pre-operation routines

-

Tasks like checking tools, topping up fluids, and warming up generators are manual and repetitive.

-

Communication & Coordination Needs

-

Improved clarity and consistency in communication

-

Firefighters sometimes received conflicting or delayed instructions during incidents.

-

-

Better intelligence before arrival

-

Responding to suicide cases was complicated by vague or inaccurate information from dispatch or bystanders.

-

-

More seamless collaboration with other agencies

-

Firefighters often coordinate with police and DART during suicide rescues, requiring smooth teamwork

-

Situational Needs

-

Overcoming language barriers with foreign victims

-

Difficulty communicating with non-English speakers during rescues adds to stress and slows response.

-

-

Faster identification of victims’ exact location

-

Time was lost trying to find victims who were not visible or misreported (e.g. on different floors or out of sight).

-

Validation Interview

1. Can you walk me through the entire SOP from the moment a suicide call comes in until the case is closed?

-

Call Activation:

-

SCDF is activated via the 995 system upon receiving a suicide-related call.

-

The Police are also notified and typically take command, especially for negotiation or legal aspects.

-

-

Initial Mobilisation:

-

Fire appliances are dispatched from the nearest station.

-

For high-rise or complex rescues, DART and an ambulance are also deployed.

-

-

En Route Preparation:

-

SCDF crew mentally reviews the SOP and prepares rescue tools (lifepack, nets, etc.).

-

-

On Arrival:

-

SCDF commander checks in with the Police commander for updates.

-

Entry or direct engagement with the victim requires police clearance.

-

SCDF cannot force entry unless life is in immediate danger and police approve.

-

-

On-Site Deployment:

-

Lifepack is set up at ground level.

-

Crew members position themselves on relevant floors for net and hook setup.

-

DART may set up rope access from the rooftop for high-angle rescues.

-

Team stays alert for sudden developments.

-

-

Victim Management:

-

If the victim is calmed or restrained, SCDF assists with securing and assessing them medically.

-

If the victim jumps or is found unconscious, SCDF performs rescue/medical response (e.g., CPR, Corpuls monitor, stretcher evacuation).

-

If the victim is deceased, the body is handed to the police and SCDF stands down.

-

-

Post-Incident Procedures:

-

Equipment is recovered post-clearance.

-

A crew debrief is held. Psychological support is provided if needed.

-

An operational report is submitted to conclude the case.

-

2. Who typically assumes the role of Incident Commander?

-

The Rota Commander of the first-arriving appliance usually becomes the Incident Commander.

-

If no Rota Commander is onboard, the most senior-ranking officer present assumes the role until a higher authority relieves them.

3. Under what circumstances would the lifepack not be deployed?

-

Not deployed if unnecessary or unsafe, such as:

-

Victim is no longer at risk (e.g., moved from the edge or safely restrained).

-

Threat is neutralised.

-

-

Not feasible in cases of:

-

Space limitations (e.g., obstructions, uneven ground, traffic).

-

Inability to align lifepack directly under jump point, making it ineffective.

-

-

Final decision is made by the Incident Commander based on safety and operational practicality.

4. How long does lifepack deployment and teardown take?

-

Deployment: Takes 5 to 10 minutes, including transporting, unfolding, and inflating with a blower.

-

Factors affecting time: Ground access, crew experience, weather, and crowd interference.

-

Teardown: Takes around 5 minutes—involves deflation, folding, and retrieval.

-

Setup phase is the most critical due to the need for precision and urgency.

5. How many crew members are required to deploy the lifepack?

-

Typically requires four firefighters under standard conditions.

-

In suicide rescue cases, more personnel from other appliances usually assist to enhance speed and accuracy.

6. What are common obstacles during deployment?

-

Space constraints due to parked cars, uneven ground, or fences—especially in urban areas.

-

Weather issues:

-

Rain reduces traction and slows setup.

-

Wind can destabilise the cushion or blower.

-

-

Crowd control: Bystanders may block access unintentionally.

-

Victim relocation: If the victim changes position (e.g., another ledge), the lifepack must be repositioned, which is difficult due to its weight and the attached blower.

7. What happens if the victim relocates after deployment?

-

SCDF must immediately reassess the new threat zone.

-

The Incident Commander decides whether to reposition the current lifepack or deploy a second one, based on urgency and resources.

-

Coordination among firefighters at different levels (ground, rooftop, inside) is critical to track movements.

-

Lifepack must stay aligned with the highest-risk location without provoking the victim.

8. How quickly can the lifepack be relocated if needed?

-

Lifepack must be partially or fully deflated before relocation, especially in tight spaces.

-

After moving, it needs to be reinflated and properly aligned.

-

Under ideal conditions with experienced crew and clear access, relocation takes 5–8 minutes.

-

Delays may occur due to terrain or limited access.

-

The urgency of the situation determines whether to relocate or deploy a second lifepack.

9. Have there been incidents where the lifepack had to be moved mid-operation?

-

Yes, when victims suddenly changed position (e.g., new window, unit, or erratic behavior).

-

The Rota Commander may authorise partial deflation for lifting and dragging.

-

Teams on rooftop and upper floors coordinate to monitor the victim during the move.

-

Relocation is done discreetly to avoid alarming the victim.

-

After repositioning, the lifepack is quickly reinflated and stabilised.

-

Success depends on precise teamwork and constant updates from observers and DART.

4.Literature Review & Market Survey

To support our findings, we reviewed literature and public statistics for evidence of the identified problems. We also explored the current market to check if existing solutions addressed these needs or left gaps our solution could fill.

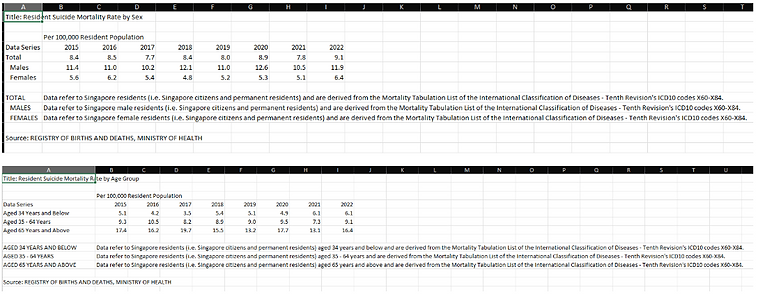

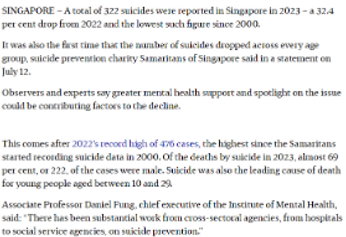

Suicide Rate

Based on these articles, the overall suicide rate has been gradually increasing over the past few years.

Existing Options (Life Pack):

Existing devices:

-

Safety life air pack

-

Body worn airbags

-

Mitsubishi Safety Airbag

-

Bagjump Airbag Systems

-

Worksafe® carabiner, 6X60mm 30Kn Break Load Capacity

Limitations of Existing "Life Pack" Solution

-

Difficult to move after deployment

-

Victim can just jump somewhere else

-

Deploying the lifepack takes between 5 to 10 minutes (including carrying and unfolding)

-

Four or more Firefighters needed to deploy lifepack

-

Large size of life air pack, can limit deployment area

5.Ideation & Design

With validated needs and insights, we entered the ideation phase brainstorming and shaping solutions tailored to each domain, guided by real user input and unmet needs.

Safety air cushion material requirement:

-

Handle repeated inflation/deflation and support human weight or impact

-

Tear-resistant, waterproof, fire-retardant

Common material:

Vinyl-reinforced fabric material:board category of material that is coated or laminated with vinyl (PVC)

-

Vinyl-reinforced polyester or nylon(widely used in inflatable products)

-

High-tension vinyl reinforced with cotton, nylon and polyester fabric (design for extreme strength or industrial used)

-

Threads: Heavy-duty synthetic threads (e.g, nylon) for high-stress seams

Types of Airbag Systems:

-

Chemical Systems

-

Sodium Azide (Historically Used)

-

Guanidine Nitrate (Modern)

-

Ammonium Nitrate (Historically Used, Unstable)

-

-

Compressed Gas Systems

-

Helium

-

Argon

-

Nitrogen

-

Stored Gas Cylinders

-

-

Hybrid Systems

-

Chemical + Compressed Gas

-

Electric Initiation w/ Gas Boost

-

Car air bag material requirement:

-

Withstand high pressure, high temperature and abrasion during rapid inflation and deflation

-

Lightweight, flexible and durable to prevent tearing or air leakage

Common material:Nylon fabric:

-

Nylon (polyamide) 6.6 as it offers high strength, heat resistance, elasticity and chemical resistance

-

Often coated with silicone or neoprene to improve airtightness and reduce friction

Issues found for each Airbag System:

-

Chemical Systems:

-

License required to acquire chemicals

-

Difficulty in controlling chemical reactions

-

Danger in utilizing toxic chemicals

-

Chemicals are potentially unstable

-

-

Compressed Gas Systems:

-

Large cylinders are required to house them

-

Helium is hard to acquire and expensive

-

-

Hybrid Systems:

-

Combined issues of the above 2 systems

-

We decided to scrap the domain, due to the difficulty in acquiring the required chemicals and the impracticality of the other methods.